Lightweight EPP molded foam packaging from Holland, Ohio, offers numerous advantages for businesses. With superior heat resistance, customizable design, and exceptional shock absorption, it protects products during transit, reduces transportation costs, and minimizes environmental impact. Its recyclability promotes sustainability in the packaging industry. Key benefits include a lightweight yet robust structure, ideal for various sectors like food, pharmaceuticals, construction, and electronics, ensuring product integrity, reducing shipping costs, and aligning with sustainability goals. Local suppliers cater to diverse client needs, making expanded polypropylene (EPP) foam solutions a versatile and eco-friendly game-changer in packaging.

“Discover the revolutionary power of heat-resistant foam inserts and their impact on product protection. This article delves into the benefits of expanded polypropylene (EPP) foam solutions, a game-changer in lightweight molded foam packaging. From enhancing product security to its wide range of applications, we explore why this innovative material is transforming industries. We’ll examine its environmental advantages, local availability in Holland, Ohio, and provide a comprehensive comparison with traditional packaging methods, highlighting the remarkable rise of EPP foam as a sustainable, efficient choice.”

- Understanding Lightweight EPP Molded Foam Packaging

- The Advantages of Using Expanded Polypropylene (EPP) Foam Solutions

- How Heat-Resistant Foam Inserts Enhance Product Protection

- Applications of Lightweight EPP Foam in Various Industries

- Comparing Traditional Packaging to EPP Foam: A Detailed Analysis

- Environmental Impact and Sustainability of EPP Foam Packaging

- Exploring the Local Availability: EPP Foam Packaging in Holland, Ohio

Understanding Lightweight EPP Molded Foam Packaging

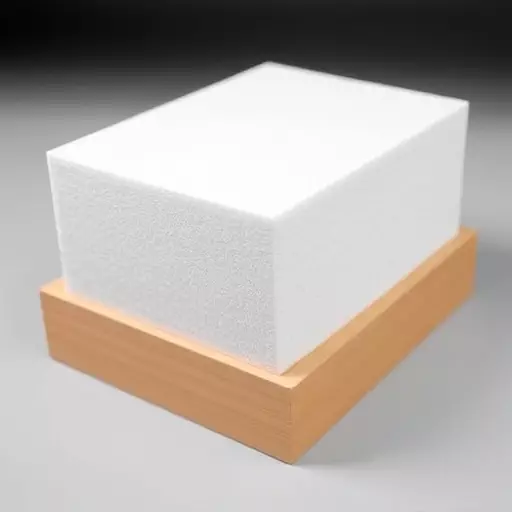

Lightweight EPP Molded Foam Packaging is a cutting-edge solution in the world of product protection and shipping. Made from expanded polypropylene (EPP), this innovative packaging material offers an array of benefits, especially for businesses based in Holland, Ohio, and beyond. It’s known for its exceptional heat resistance, making it ideal for protecting sensitive or temperature-prone items during transit. EPP foam’s lightweight nature is a game-changer; it reduces overall transportation costs while minimizing the environmental impact.

This molded foam packaging is versatile and can be customized to fit various product shapes and sizes. Its unique cellular structure provides excellent shock absorption, ensuring products arrive undamaged. Moreover, EPP foam solutions are easily recyclable, contributing to a more sustainable packaging industry. With its combination of durability, lightweight properties, and heat resistance, lightweight EPP molded foam packaging is a preferred choice for businesses seeking efficient and effective protection for their goods.

The Advantages of Using Expanded Polypropylene (EPP) Foam Solutions

Expanded Polypropylene (EPP) foam solutions offer a myriad of advantages in various industries, particularly when it comes to packaging and insulation. One of its key attributes is lightweight construction—a significant benefit for shipping and transportation purposes. EPP’s unique cellular structure provides exceptional strength while maintaining an extremely low density, making it ideal for protecting fragile items without adding substantial weight.

Located in Holland, Ohio, these molded foam packaging solutions are versatile and cost-effective. They can be easily customized to fit specific product dimensions, ensuring optimal protection during transit. Moreover, EPP is heat-resistant, making it suitable for applications that require insulation from temperature fluctuations. This property not only extends the lifespan of perishable goods but also makes EPP a preferred choice in industries where maintaining product integrity is paramount.

How Heat-Resistant Foam Inserts Enhance Product Protection

Heat-resistant foam inserts play a pivotal role in enhancing product protection, especially for items that are sensitive to temperature variations. These lightweight yet robust EPP (expanded polypropylene) molded foam packaging solutions are designed to offer unparalleled shock absorption and insulation. By encapsulating products within a carefully crafted foam environment, they mitigate the risks associated with heat exposure during transit or storage. This is particularly beneficial for industries like food and pharmaceuticals, where maintaining product integrity is paramount.

The benefits of EPP foam packaging are numerous. Firstly, it provides a customizable fit for various product shapes and sizes, ensuring that delicate items are secured without causing damage. Secondly, its excellent thermal resistance prevents sudden temperature changes, which can cause degradation or spoilage. This feature is particularly notable in regions like Holland, Ohio, where extreme weather conditions may pose challenges to traditional packaging methods. Expanded polypropylene foam solutions offer a lightweight alternative to denser materials, reducing shipping costs and carbon footprints while maintaining exceptional product protection.

Applications of Lightweight EPP Foam in Various Industries

Lightweight EPP molded foam is a versatile material with numerous applications across various industries. Known for its exceptional heat resistance and rigid structure, it’s particularly valued in sectors requiring specialized packaging solutions. In the food industry, for example, lightweight EPP foam inserts are used to protect delicate items during shipping, ensuring they arrive intact and fresh. Its insulating properties make it ideal for keeping perishable goods at the right temperature, enhancing product quality and safety.

Beyond food, expanded polypropylene (EPP) foam solutions find use in a wide range of industries. In construction, it acts as an effective insulation material, contributing to energy-efficient buildings. Automotive manufacturers utilize EPP for various components, taking advantage of its light weight and ability to absorb impact without compromising structural integrity. Its versatility extends to the electronics sector, where it serves as protective packaging for delicate devices during transportation, safeguarding them from potential damage.

Comparing Traditional Packaging to EPP Foam: A Detailed Analysis

In the realm of product protection and shipping, the transition from traditional packaging to Lightweight EPP molded foam packaging Holland Ohio has brought about significant changes. Expanded Polypropylene (EPP) foam solutions offer a range of benefits that traditional packaging methods struggle to match. One of the key advantages is its lightweight nature; EPP foam is remarkably thin yet highly effective in cushioning and protecting products during transit. This attribute reduces overall shipping costs, as less material means lower freight expenses.

Furthermore, EPP foam provides superior shock absorption, making it ideal for fragile items. Its cellular structure creates a soft, compressible material that minimizes the impact of sudden movements or drops, ensuring products arrive undamaged. Unlike traditional packaging that may involve multiple layers and materials, EPP foam offers an efficient, single-layer solution, simplifying the packing process and reducing waste. This eco-friendly approach aligns with modern sustainability goals, making it a popular choice for environmentally conscious businesses.

Environmental Impact and Sustainability of EPP Foam Packaging

The environmental impact and sustainability of EPP (Expanded Polypropylene) foam packaging have gained significant attention in recent years. This lightweight epp molded foam packaging, available in places like Holland, Ohio, offers a range of benefits for businesses and consumers alike. By utilizing expanded polypropylene foam solutions, companies can reduce their carbon footprint compared to traditional packaging materials, which often rely heavily on non-biodegradable substances.

EPP foam is highly recyclable and biodegradable, making it an eco-friendly alternative. Its production process consumes fewer resources and generates less waste than many other packaging options. Moreover, this type of foam packaging is designed to be durable yet lightweight, ensuring efficient transportation and storage while minimizing the environmental toll associated with shipping. The benefits of EPP foam packaging extend beyond sustainability; its excellent insulation properties make it versatile for various applications, further contributing to its growing popularity in both industrial and retail sectors.

Exploring the Local Availability: EPP Foam Packaging in Holland, Ohio

In Holland, Ohio, exploring local availability options for heat-resistant foam inserts reveals a vibrant landscape of lightweight EPP molded foam packaging solutions. These innovative products are transforming various industries, offering numerous benefits such as exceptional insulation properties, cost-effectiveness, and environmental sustainability due to their recycled content. Expanded polypropylene (EPP) foam is not just a game-changer in packaging; it’s also a versatile material used in construction, automotive, and even sports equipment for its lightweight yet robust nature.

The local market in Holland, Ohio, abounds with suppliers offering tailored EPP foam packaging solutions to meet specific client needs. This accessibility ensures businesses across sectors can leverage the advantages of expanded polypropylene foam without compromise. From protecting delicate electronics during transit to ensuring food remains fresh and safe, these heat-resistant foam inserts are a reliable choice. Their lightweight construction reduces shipping costs and environmental impact while maintaining superior insulation, making them an ideal solution for modern, eco-conscious businesses.